WATER MONITORING and CONTROL

Revolutionizing Water Quality with Advanced Oxygen Infusion Technology

Information on Controllers, Sensors, IoT, and Smart Farming

Why Dissolved Oxygen is Vital

Dissolved Oxygen plays a pivotal role as an indicator of water quality due to its direct influence on biological and chemical processes within aquatic ecosystems. It is a key parameter that significantly impacts the health and vitality of aquatic life, ranging from microscopic organisms to fish and other species that inhabit our waters.

Maintaining optimal DO levels is essential for the thriving of aquatic organisms and the preservation of ecological balance. Conversely, low DO levels can lead to hypoxia, a condition characterized by oxygen deprivation. This phenomenon can result in severe consequences, such as fish kills, reduced biodiversity, and the disruption of entire ecosystems.

The Role of Ultra-Oxygen Generation

The Impact on Other Parameters

The measurement of Dissolved Oxygen has a profound impact on other important water quality parameters. Nutrient levels, such as nitrogen and phosphorus, directly influence the growth of aquatic plants and algae. Insufficient oxygen due to excessive nutrient loading can trigger harmful algal blooms, leading to oxygen depletion and ecological imbalances.

Additionally, the decomposition of organic matter is closely tied to DO levels. Inadequate oxygen supply can result in the release of harmful byproducts, contributing to water pollution and adverse effects on aquatic organisms. By ensuring sufficient levels of Dissolved Oxygen, we support the natural processes of organic matter decomposition while minimizing the potential for water contamination.

In conclusion, monitoring Dissolved Oxygen is not merely a technical exercise but a crucial step in safeguarding the health and balance of our water ecosystems. With Ultra-Oxygen Monitoring, we utilize advanced micro and ultrafine generators to efficiently introduce oxygen molecules into the water, enhancing DO levels and promoting a healthy aquatic environment.

Choose Ultra-Oxygen Monitoring for accurate and reliable Dissolved Oxygen measurements, backed by factual evidence and references. Together, let’s preserve the sustainability and vitality of our water resources for generations to come, ensuring a thriving ecosystem for all living organisms.

What’s dissolved oxygen (DO)?

Dissolved oxygen (DO) is the existence of free, non-compound oxygen present in water or other liquids, gaseous, molecular oxygen in the form of O2, not bonded to any other element, naturally originating from the atmosphere or as a by-product of photosynthesis.

The bonded oxygen molecule in water (H2O) is in a compound and does not count toward dissolved oxygen levels. One can imagine that free oxygen molecules dissolve in water much the way salt or sugar does when it is stirred.

Once dissolved in water, it is available for use by fish, invertebrates, aquatic plants, plants, animals, good bacteria, and all other living organisms. DO plays a significant role in many chemical processes in the aquatic environment and is considered the most important measure of water quality as it is a direct indicator of an aquatic resource’s ability to support aquatic life.

Microbes such as bacteria and fungi require dissolved oxygen (DO) to decompose organic material in water. Microbial decomposition is a crucial contributor to nutrient recycling and if there is an excess of pollution and decaying organic material (from dying algae and other organisms), the oxygen levels will get used up quicker.

Anaerobic conditions then occur when the uptake or disappearance of oxygen is greater than its production by photosynthesis, diffusion, or aeration. Many anaerobic bacteria produce enzymes that destroy tissue or sometimes release potent toxins.

The only way to restore nature in this state is to add oxygen back to the water, and here lies the challenge.

Normal aeration bubbles only contain 21% oxygen, rise too fast and require a high energy source to transfer enough oxygen to restore the water in an aerobic condition.

Ultra-Oxygen Micro and Ultrafine bubble-generating technology solved this problem by creating bubbles that rise very slowly and can stay in water for months if not used. This allows the use of oxygen generators that produce up to 93% oxygen efficiently for the first time in the history of aeration.

Dissolved oxygen is usually reported in milligrams per liter (mg/L), as a percent (%) of air saturation, or in parts per million (ppm). 1 mg/L is equal to 1 ppm.

Dissolved oxygen is an essential factor for the activity of microbial biocatalysts used in enhanced bioremediation, as it is a key component for aerobic respiration, the primary metabolic pathway for many microorganisms.

During aerobic respiration, microorganisms use oxygen to break down organic compounds into energy, carbon dioxide, and water. This process releases energy that can be used to fuel microbial growth and metabolism. In the context of bioremediation, microorganisms use this process to break down contaminants in contaminated environments such as soil or water.

The presence of dissolved oxygen in the environment promotes the growth and activity of aerobic microorganisms that can degrade pollutants, such as hydrocarbons and other organic compounds, more efficiently than anaerobic microorganisms. By providing sufficient dissolved oxygen, the bioremediation process can be accelerated, allowing for faster and more complete removal of contaminants from the environment.

Therefore, the availability of dissolved oxygen is critical for the activity of aerobic microorganisms and the success of enhanced bioremediation techniques that rely on these microorganisms as biocatalysts. In situations where dissolved oxygen is limited, alternative remediation approaches may need to be considered, such as anaerobic bioremediation or the use of other non-biological remediation methods.

Ultra-Oxygen micro and ultrafine bubble (MB/UFB) generators transfer more oxygen into the water compared to conventional aeration techniques, creating a more oxygen-rich environment that can enhance the activity of aerobic microorganisms involved in bioremediation. This increased oxygen supply helps to improve the metabolic activity of microorganisms, promoting their growth and increasing their biocatalytic efficiency.

Using MB/UFB technology also helps to reduce the toxicity of pollutants by promoting the biodegradation of contaminants into less harmful compounds. This can be particularly important for the bioremediation of organic pollutants, such as petroleum hydrocarbons, where UFBs can enhance the activity of aerobic and anaerobic microorganisms involved in the degradation process.

Overall, the use of MB/UFBs in microbial biocatalysts for enhanced bioremediation can help to improve the efficiency and effectiveness of the bioremediation process, making it a promising technology for the treatment of contaminated water and soil.

Ultra-Oxygen dissolved oxygen meters, sensors, and water monitoring equipment can be used to monitor water quality parameters.

“If you can’t measure it, you can’t manage it.”

Measuring Dissolved Oxygen (DO) and sensors used

How is dissolved oxygen measured?

Dissolved oxygen is mostly measured in the field with DO meters that are connected to a sensor. The three commonly used sensors are:

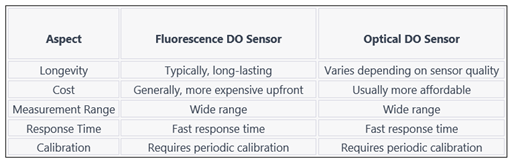

FLUORESCENCE & OPTICAL (1st choice.) (Longest lifespan, most expensive, most reliable, needs the least maintenance and spare parts, does not need electrolyte and regular calibration, requires little skill to operate.),

POLAROGRAPHIC (2nd choice.) (longer lifespan than galvanic sensors, less expensive, reliable, need to replace membrane and electrolyte, calibration required when replacing electrolyte and membrane, require some skill to operate), and

GALVANIC (last choice.) (least expensive, not always reliable all the time, needs to replace membrane and electrolyte frequently, calibration required most of the time, requires a lot of skill to operate) type sensors.

Fluorescence and Optical DO sensors

Like electrochemical sensors, no reagents are required when using optical sensors. The sensor cap of an optical DO sensor contains a diffusion layer across which DO is constantly moving. Unlike electrochemical sensors, oxygen is not consumed during the measurement, so water does not need to flow continuously across the sensor cap.

A fluorescence DO sensor utilizes the principle of oxygen quenching to measure the concentration of dissolved oxygen. It contains a fluorophore (a fluorescent molecule) that emits light when excited by a light source. When oxygen molecules come into contact with the fluorophore, they quench its fluorescence, reducing the emitted light intensity. By measuring the decrease in fluorescence, the sensor can determine the concentration of dissolved oxygen.

On the other hand, an optical DO sensor, also known as an oxygen optode, relies on the oxygen-dependent luminescence quenching of a special oxygen-sensitive dye. The sensor typically consists of a thin film containing the dye, which is excited by a light source. The dye emits light that is quenched by oxygen molecules in the surrounding medium. The rate of quenching is proportional to the concentration of dissolved oxygen, allowing the sensor to measure oxygen levels.

Both fluorescence DO sensors and optical DO sensors provide accurate measurements of dissolved oxygen. However, they employ different techniques and sensor designs to achieve this.

Optical sensors have the longest lifespan of all sensors on the market.

Electrochemical Sensors

The most used sensors are Electrochemical Sensors. There are two types of electrochemical sensors – (A) Polarographic and (B) Galvanic. Electrochemical DO sensors consist of an anode and a cathode confined in an electrolyte solution by an oxygen-permeable membrane. Oxygen molecules dissolved in the sample diffuse through the membrane before being reduced (i.e., consumed) at the cathode. This reaction produces an electrical signal that travels from the cathode to the anode, ultimately reaching the instrument/meter.

Polarographic

Polarographic sensors have a gold, silver or platinum alloy cathode, and silver anode immersed in an electrolyte of photic and potassium chloride solution in water. A thin gas-permeable Teflon membrane allows the diffusion of oxygen from the water sample.

The chemical reactions that take place are shown below.

Since for each oxygen molecule that is reduced four electrons enter the cell and four leave the anode an electrical current is obtained from the cathode to the anode that is directly proportionate to the amount of oxygen that passes through the membrane. The optimum voltage between the anode and cathode that allows selecting the FREE oxygen component in the water is 0.8 volt DC.

Measurement accuracy of 1% = 0,2 ppm or mg/L and 2 ppb is 5% of the reading.

Polarographic sensors have a longer lifespan than galvanic sensors.

Galvanic

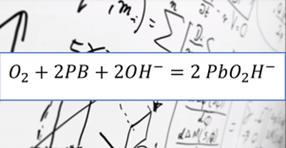

The Galvanic technique is characterised by the fact that it produces its own electric current thanks to the reduction of oxygen at the cathode. The sensors have a lead or silver anode, and the cathode is silver with a potation hydroxide electrolyte. It is used when the potential difference between the cathode and the anode is less than 0.05 volts being the global reaction below.

The materials used in this sensor allow the sensor to be continuously polarized even when the meter is off, so no warm-up period is required. A drawback to always being on is that these sensors have a shorter life than polarographic sensors.

Conductivity, Salinity, TDS, and Turbidity sensors

Conductivity sensors are utilized to measure ion concentrations, salinity sensors focus on salt content, TDS sensors estimate the overall concentration of dissolved substances, and turbidity sensors assess the presence of suspended particles. Each type of sensor serves a specific purpose in monitoring and understanding different aspects of liquid samples in various industries and research fields.

Here’s a summary of the purposes and applications of the four types of sensors:

Conductivity Sensor

Conductivity sensors are used to measure the electrical conductivity of a solution. They are commonly employed in water quality monitoring, hydroponics, and industrial processes to assess the concentration of ions in the solution. Conductivity measurements help in evaluating water purity, determining salinity levels, and monitoring chemical processes.

Salinity Sensor

Salinity sensors specifically measure the salt content or salinity of a solution. They are essential in marine and aquatic applications, such as oceanography, aquaculture, and desalination plants. Salinity measurements help in assessing water quality, understanding marine ecosystems, and monitoring the effectiveness of desalination processes.

TDS Sensor

TDS sensors are used to measure the total dissolved solids in a solution. They provide an overall estimate of the concentration of inorganic and organic substances present in a dissolved form. TDS measurements are valuable in water quality assessment, hydroponics, and industrial processes to evaluate the presence of dissolved contaminants, assess water purity, and monitor the effectiveness of filtration or purification methods.

Turbidity Sensor

Turbidity sensors measure the cloudiness or turbidity of a liquid sample, which indicates the presence of suspended particles. They find applications in water quality monitoring, environmental assessment, and research. Turbidity measurements are used to evaluate water clarity, detect changes in sediment levels, and assess the impact of pollutants or natural processes on water bodies.

Using conductivity, salinity, TDS, and turbidity sensors provides several benefits in various applications and industries:

Water Quality Monitoring

These sensors enable accurate and real-time monitoring of water quality parameters, helping to ensure the safety and suitability of water for different purposes such as drinking water, aquaculture, and industrial processes. They provide valuable data for assessing water contamination, identifying changes in water composition, and detecting potential issues early on.

Environmental Monitoring

The sensors play a crucial role in monitoring and assessing the health of aquatic ecosystems, including rivers, lakes, and oceans. They aid in evaluating the impact of pollutants, sedimentation, and other factors on water bodies, assisting in environmental conservation and management efforts.

Process Optimization

In industrial processes, these sensors help optimize operations by providing data on conductivity, salinity, TDS, and turbidity. By monitoring and controlling these parameters, manufacturers can ensure consistent product quality, reduce waste and rejections, and enhance process efficiency.

Research and Scientific Studies

Conductivity, salinity, TDS, and turbidity sensors are widely used in research and scientific studies related to water quality, hydrology, environmental sciences, and marine biology. These sensors provide valuable data for understanding natural processes, studying ecosystem dynamics, and conducting experiments in controlled environments.

Agricultural and Hydroponic Systems

Conductivity sensors are particularly useful in agricultural applications, such as soil and nutrient management. They help farmers assess soil salinity, optimize irrigation practices, and ensure proper nutrient levels for crop growth. In hydroponic systems, these sensors aid in maintaining optimal nutrient solutions for plant cultivation.

Water Treatment and Desalination

These sensors assist in water treatment processes, such as monitoring the efficiency of filtration, ion exchange, and disinfection methods. In desalination plants, conductivity and salinity sensors play a crucial role in monitoring the desalination process and ensuring the quality of the produced fresh water.

| Aspect | Conductivity Sensor | Salinity Sensor | TDS Sensor | Turbidity Sensor |

|---|---|---|---|---|

| Measurement Parameter | Electrical conductivity | Salinity (salt content) | Total Dissolved Solids | Turbidity (cloudiness) |

| Measurement Units | Siemens per meter (S/m) or µS/cm | Parts per thousand (ppt) or PSU | Parts per million (ppm) or mg/L | Nephelometric Turbidity Units (NTU) |

| Principle | Measures electrical conductivity | Converts conductivity to salinity | Measures conductivity, estimates TDS | Measures light scattering by particles |

| Calibration | Requires periodic calibration | Requires calibration for salinity | Requires periodic calibration | Requires periodic calibration |

| Application | Water quality monitoring, hydroponics, industrial processes | Marine and aquatic applications, desalination plants | Water quality assessment, hydroponics, industrial processes, environmental monitoring | Water quality monitoring, environmental monitoring, research |

| Sensor Design | Two or four electrodes in contact with the solution | Can incorporate additional sensors or techniques for improved accuracy | Can incorporate additional sensors or techniques for improved accuracy | Light source and detector for measuring scattered light |

| Interference | Affected by temperature, presence of other ions or substances, sensor fouling | Affected by temperature, other ions or substances, sensor fouling | Affected by temperature, presence of other ions or substances, sensor | Affected by temperature, presence of particles, sensor fouling |

Understanding TSS and Turbidity: Ensuring Water Quality

Introduction

Total Suspended Solids (TSS) and Turbidity are two essential parameters used to assess water quality. It is strongly recommended to understand the definitions of TSS and Turbidity, their significance, and their importance in maintaining clean and healthy water resources.

What is TSS?

Total Suspended Solids (TSS) refers to the total mass of particles suspended in a liquid that can be retained by a filter. These particles may include sediment, silt, or organic matter. TSS is measured in milligrams per litre (mg/L) and serves as a crucial indicator of water quality.

What is Turbidity?

Turbidity is a measure of the cloudiness or haziness of a liquid caused by suspended particles. It quantifies the scattering of light by these particles in the water. Turbidity is typically expressed in Nephelometric Turbidity Units (NTU) and provides valuable insights into the clarity and overall quality of water.

Importance of TSS and Turbidity

Water Quality Assessment: TSS and Turbidity measurements are fundamental for assessing the cleanliness and health of water resources. High levels of TSS indicate the presence of suspended solids, potentially compromising water quality and impacting aquatic ecosystems.

Drinking Water Treatment: Monitoring TSS and Turbidity is critical in the treatment of drinking water. Elevated TSS can hinder disinfection processes, while high Turbidity levels may reduce the effectiveness of disinfectants. These measurements ensure the delivery of safe and potable drinking water to communities.

Environmental Impact: Excessive TSS and Turbidity can have detrimental effects on aquatic life. Sediment runoff and high turbidity levels can impede light penetration, inhibiting photosynthesis and disrupting the food chain. By monitoring these parameters, we can identify sources of pollution and protect fragile ecosystems.

Regulatory Compliance: TSS and Turbidity limits are often established by regulatory agencies to safeguard water quality. Compliance with these standards is essential for industries, wastewater treatment plants, and other entities to ensure they meet environmental regulations and prevent harmful impacts.

Why the two different units of measurement are used? (NTU vs mg/L)

NTU (Nephelometric Turbidity Unit) and mg/L (milligrams per litre) are two different units used to measure different properties in water.

NTU is a unit of measurement for turbidity, which refers to the cloudiness or haziness of a liquid caused by suspended particles. It is commonly used to assess water quality, particularly in terms of the presence of sediment, silt, or other particulate matter. NTU is measured using a nephelometer, which quantifies the amount of light scattered by particles in a water sample. The higher the NTU value, the greater the turbidity or cloudiness of the water.

On the other hand, mg/L is a unit of measurement for the concentration of a substance in a solution. It represents the amount of mass (in milligrams) of a solute dissolved in a given volume (in litres) of the solvent. This unit is often used in water analysis to express the concentration of various contaminants or constituents, such as chemicals, minerals, or pollutants.

It’s important to note that NTU and mg/L are not directly convertible to each other because they measure different characteristics of water. NTU measures turbidity, while mg/L measures concentration. The relationship between the two depends on the specific composition of the suspended particles causing the turbidity.

Side-by-Side Comparison: TSS vs. Turbidity

| Property | TSS (Total Suspended Solids) | Turbidity |

|---|---|---|

| Definition | Total mass of suspended particles in a liquid | Measure of the cloudiness or haziness of a liquid due to suspended particles |

| Measurement | Typically expressed in milligrams per litre (mg/L) | Typically expressed in Nephelometric Turbidity Units (NTU) |

| Type of Measurement | Concentration measurement | Optical measurement |

| Particle Size | Includes all particles capable of being retained by a filter | Primarily measures the scattering of light by particles in the water |

| Indication of Water Quality | Reflects the presence of suspended solids in the water | Reflects the degree of cloudiness or haziness in the water |

| Environmental Impact | High TSS levels can affect aquatic life, water clarity, and natural processes | High turbidity levels can impact aquatic ecosystems, light penetration, and habitat |

| Drinking Water Treatment | TSS measurement helps assess the need for additional treatment steps | Turbidity measurement ensures the efficiency of disinfection processes |

| Regulatory Compliance | TSS limits are often established for various water bodies and purposes | Turbidity limits are established by regulatory agencies |

| Engineering Considerations | TSS can affect the efficiency and lifespan of water infrastructure | Turbidity can impact the operation and maintenance of water systems |

Clear Water Does Not Always Mean Safe Drinking Water

Clear water can be deceiving when it comes to assessing its safety for drinking. It’s important to understand that water’s visual appearance alone does not guarantee its purity. Here’s why:

Microbial Contamination: Clear water does not necessarily indicate the absence of harmful microorganisms. Disease-causing bacteria, viruses, and parasites can be present even in clear-looking water. These microscopic contaminants are invisible to the naked eye but can pose serious health risks if ingested.

Chemical Contaminants: The absence of turbidity or suspended solids does not imply the absence of chemical contaminants. Water can contain various chemicals such as pesticides, heavy metals, industrial pollutants, or naturally occurring substances, even if it appears crystal clear. These contaminants cannot be detected through visual observation alone.

Waterborne Diseases: Clear water can still harbour pathogens responsible for waterborne diseases such as cholera, giardiasis, or cryptosporidiosis. These diseases can have severe health consequences, especially in areas with inadequate sanitation or compromised water sources.

Treatment Requirements: Clear water does not eliminate the need for proper water treatment. Regardless of its appearance, all water sources should undergo appropriate treatment processes to remove or inactivate harmful pathogens, chemical contaminants, and other impurities.

Water Quality Testing: Regular water quality testing is essential to ensure the safety of drinking water. Laboratory analysis can detect contaminants that are invisible to the naked eye, providing a comprehensive understanding of the water’s suitability for consumption.

Conclusion: Look Beyond Appearance and remember, that clear water does not always equate to safe drinking water. While visual assessment can give an initial impression, it is imperative to rely on comprehensive water quality testing and appropriate treatment measures. Do not be fooled by the appearance of water; prioritize ensuring its safety through thorough analysis and treatment.

BOD, COD and Blue-green Algae Sensors

The importance of using these sensors:

BOD Sensor

BOD sensors provide vital information about the level of organic pollution in water bodies. Monitoring BOD helps assess the effectiveness of wastewater treatment processes, identify pollution sources, and evaluate the impact of discharges on the receiving environment. It plays a crucial role in ensuring water quality and protecting aquatic ecosystems.

COD Sensor

COD sensors measure the amount of oxidizable substances in a water sample. This parameter helps determine the pollution potential and organic load present in the water. Monitoring COD aids in assessing treatment efficiency, optimizing chemical dosing, and complying with regulatory requirements for wastewater discharge.

Blue-green Algae Sensor

Blue-green algae sensors detect the presence and concentration of blue-green algae, also known as cyanobacteria, in water bodies. These sensors can identify specific pigments or genetic markers associated with blue-green algae. Early detection of blue-green algae blooms is crucial for taking timely measures to mitigate potential health risks, such as toxin production and oxygen depletion, and to protect aquatic ecosystems.

Side-by-side comparisons

| Aspect | BOD Sensor | COD Sensor | Blue-green Algae Sensor |

|---|---|---|---|

| Measurement Parameter | Biochemical Oxygen Demand (BOD) | Chemical Oxygen Demand (COD) | Presence and concentration of blue-green algae |

| Measurement Units | Milligrams per Liter (mg/L) | Milligrams per Liter (mg/L) | Cells per millilitre (cells/mL) |

| Principle | Measures the oxygen consumed by microorganisms during the degradation of organic matter | Measures the oxygen equivalent of the oxidizable substances in a sample | Detects specific pigments or genetic markers associated with blue-green algae |

| Calibration | Requires periodic calibration | Requires periodic calibration | Requires periodic calibration |

| Application | Water quality assessment, wastewater treatment, environmental monitoring | Water quality assessment, wastewater treatment, environmental monitoring | Environmental monitoring, algae bloom detection |

| Importance | – Provides information about the organic pollution level in water | – Determines the organic load and pollution potential of a water sample | – Early detection of blue-green algae blooms to mitigate potential health and environmental risks |

| - | – Indicates the level of microbial activity and oxygen depletion in water | – Helps evaluate treatment efficiency | - |

| - | - | – Assists in complying with regulatory requirements for wastewater discharge | - |

Chlorophyll-a, Nitrate(NO3-) and Ammonia Nitrogen(NH4-N) sensors

The importance of using these sensors:

Chlorophyll-a Sensor

Chlorophyll-a sensors are used to measure the concentration of chlorophyll-a, which is a pigment found in photosynthetic organisms such as algae and cyanobacteria. Monitoring chlorophyll-a levels provides insights into the presence and abundance of these organisms in water bodies. It helps in assessing water quality, monitoring algal blooms, studying ecological dynamics, and understanding the impact of nutrient enrichment on aquatic ecosystems.

Nitrate Sensor

Nitrate sensors quantify the concentration of nitrate (NO3-), which is an essential nutrient for plant growth. Monitoring nitrate levels is crucial for assessing water quality, particularly in agricultural runoff and drinking water sources. Excessive nitrate levels can lead to eutrophication, harmful algal blooms, and potential health risks, making nitrate sensors vital for managing nutrient pollution and protecting human and environmental health.

Ammonia Nitrogen Sensor

Ammonia nitrogen sensors measure the concentration of ammonia nitrogen (NH3/NH4+). Ammonia nitrogen is a byproduct of organic decomposition and nitrogenous waste. High levels of ammonia nitrogen can be toxic to aquatic organisms, indicating pollution sources and poor water quality. Monitoring ammonia nitrogen is important in environmental monitoring, particularly in wastewater treatment processes, to ensure compliance with regulatory standards and prevent harmful effects on aquatic life.

Aquaponics and wastewater treatment rely on the delicate interplay of key parameters to achieve optimal efficiency and sustainability. Monitoring chlorophyll-a, nitrate, and ammonia nitrogen levels is vital to maintaining a balanced ecosystem and unlocking the full potential of these systems.

Chlorophyll-a sensors provide valuable insights into the presence and abundance of photosynthetic organisms. By monitoring chlorophyll-a levels, we can assess the overall health of the aquaponic system or wastewater treatment process, optimizing conditions for plant growth and fostering a thriving ecosystem.

Nitrate sensors are essential tools for both aquaponics and wastewater treatment. They help measure the concentration of nitrate, a key component of the nitrogen cycle. Monitoring nitrate levels allows us to assess the efficiency of nitrification processes and maintain an adequate nutrient supply for plant growth. In wastewater treatment, nitrate sensors aid in optimizing de-nitrification, reducing nitrogen compounds and minimizing environmental impact.

Ammonia nitrogen sensors play a pivotal role in both aquaponics and wastewater treatment systems. They enable us to monitor the concentration of ammonia nitrogen, a potential toxin to aquatic organisms. By ensuring optimal ammonia nitrogen levels, we protect the health of fish and other species in aquaponics. In wastewater treatment, ammonia nitrogen sensors assist in evaluating nitrification efficiency and reducing environmental pollution.

The Power of Nitrification and De-nitrification

Sustainable Nutrient Cycling

Nitrification, the conversion of ammonia to nitrate, is a vital process in aquaponics and wastewater treatment. By harnessing nitrification, we transform toxic ammonia into a plant-available form, promoting healthy plant growth and sustainable food production in aquaponics. In wastewater treatment, nitrification reduces ammonia levels, ensuring safe effluent discharge and preserving water quality.

De-nitrification complements nitrification in both aquaponics and wastewater treatment. This process converts nitrate into harmless nitrogen gas, preventing its accumulation and potential environmental harm. De-nitrification reduces nitrogen loads, ensuring compliance with regulatory standards and protecting water bodies from pollution.

The integration of chlorophyll-a, nitrate, and ammonia nitrogen sensors empowers us to make informed decisions and optimize nitrification and de-nitrification processes. Real-time monitoring enables precise control of nutrient levels, minimizing waste and maximizing the benefits of these essential processes.

Side-by-side comparisons

| Aspect | Chlorophyll-a Sensor | Nitrate Sensor | Ammonia Nitrogen Sensor |

|---|---|---|---|

| Measurement Parameter | Concentration of chlorophyll | Concentration of nitrate (NO3-) | Concentration of ammonia nitrogen (NH3/NH4+) |

| Measurement Units | Micrograms per Liter (µg/L) | Milligrams per Liter (mg/L) | Milligrams per Liter (mg/L) |

| Principle | Measures specific pigments in photosynthetic organisms | Utilizes chemical reactions to quantify nitrate concentration | Utilizes chemical reactions to quantify ammonia nitrogen concentration |

| Application | Water quality assessment, monitoring algal blooms, ecological studies | Environmental monitoring, agricultural runoff, drinking water analysis | Environmental monitoring, wastewater treatment |

| Importance | – Indicates the presence and abundance of photosynthetic organisms in water | – Nitrate levels impact water quality, aquatic ecosystems, and human health | – Ammonia nitrogen is toxic to aquatic organisms and indicates pollution sources |

| - | - | – High nitrate levels can lead to eutrophication and harmful algal blooms | – High ammonia nitrogen levels can lead to toxicity, fish kills, and impaired water quality |

Residual Chlorine and Dissolved Ozone Sensor

The importance of using these sensors

Residual Chlorine Sensor

Residual chlorine sensors measure the concentration of free chlorine remaining in water after disinfection processes. Monitoring residual chlorine levels is crucial for ensuring the effectiveness of water disinfection and treatment processes. It helps in maintaining water safety, protecting public health by preventing the spread of waterborne diseases, and complying with regulatory standards for drinking water quality.

Dissolved Ozone Sensor

Dissolved ozone sensors are used to measure the concentration of ozone gas dissolved in water. Ozone is a powerful oxidant and disinfectant commonly used in water treatment processes. Monitoring dissolved ozone levels is important in ozone-based disinfection systems to ensure efficient disinfection, control microbial growth, and eliminate organic contaminants. Real-time monitoring helps in maintaining optimal ozone dosing and process control.

Using these sensors provides critical information for water disinfection and treatment processes. They help in ensuring the effectiveness of disinfection, maintaining appropriate residual levels for disinfection, and protecting public health. Additionally, dissolved ozone sensors are valuable in ozone-based water treatment systems, where monitoring ozone levels ensures efficient disinfection and process optimization.

Side-by-side comparisons

| Aspect | Residual Chlorine Sensor | Dissolved Ozone Sensor |

|---|---|---|

| Measurement Parameter | Concentration of residual chlorine | Concentration of dissolved ozone |

| Measurement Units | Parts per million (ppm) or milligrams per Liter (mg/L) | Parts per million (ppm) or milligrams per Liter (mg/L) |

| Principle | Utilizes chemical reactions to measure the concentration of free chlorine residual in water. | Utilizes electrochemical reactions or UV absorption to measure the concentration of dissolved ozone in water. |

| Application | Water disinfection monitoring, drinking water analysis, wastewater treatment, swimming pools, and industrial processes. | Water treatment processes, ozone-based disinfection systems, environmental monitoring. |

| Importance | – Ensures the effectiveness of disinfection processes and public health protection. | – Monitors the concentration of dissolved ozone in water treatment processes. |

| – Indicates the presence of free chlorine residual, which can be an indicator of water safety and sanitation. | – Provides real-time monitoring of dissolved ozone levels for efficient disinfection and process control. | |

| – Helps in maintaining adequate residual chlorine levels in swimming pools and water distribution systems. | – Ozone is a powerful disinfectant that can inactivate microorganisms. and eliminate organic contaminants. |

Recommended Materials for Sensors

PEEK

Polyetheretherketone (PEEK) is a high-performance thermoplastic polymer known for its exceptional mechanical, thermal, and chemical properties. It belongs to the family of polyaryletherketones and is widely used in various industries due to its unique combination of properties.

Characteristics of PEEK: High-Temperature Resistance: PEEK exhibits excellent thermal stability, allowing it to maintain its mechanical properties at high temperatures. It has a high glass transition temperature (Tg) of around 143°C (289°F) and can withstand continuous use at elevated temperatures up to approximately 250°C (482°F).

Mechanical Strength: PEEK possesses exceptional mechanical strength and stiffness, making it suitable for demanding applications. It has a high tensile strength, excellent fatigue resistance, and good impact resistance.

Chemical Resistance: PEEK demonstrates resistance to a wide range of chemicals, including acids, bases, organic solvents, and hydrocarbons. It is also highly resistant to steam, radiation, and various sterilization methods.

Wear and Friction Properties: PEEK has low friction and excellent wear resistance, making it suitable for applications involving sliding or moving parts.

Electrical Insulation: PEEK is an excellent electrical insulator, offering high dielectric strength and low electrical conductivity.

Biocompatibility: PEEK is biocompatible, meaning it is well-tolerated by the human body. This property makes it suitable for medical and dental applications, such as implants, surgical instruments, and prosthetics.

POM

POM, also known as Polyoxymethylene or Acetal, is a high-performance engineering thermoplastic characterized by its excellent mechanical properties, low friction, and dimensional stability. It is widely used in various industries due to its desirable combination of properties.

Characteristics of POM: Mechanical Strength: POM exhibits high tensile strength, stiffness, and impact resistance. It maintains its mechanical properties even under continuous load and performs well in demanding applications.

Low Friction and Wear Resistance: POM has a low coefficient of friction, making it suitable for applications where low wear and smooth movement are required. It has excellent resistance to abrasion and sliding wear.

Dimensional Stability: POM has low moisture absorption, providing good dimensional stability over a wide range of temperatures. It retains its shape and size, making it suitable for precision parts and components.

Chemical Resistance: POM is resistant to many chemicals, including solvents, fuels, oils, and alkalis. It exhibits good resistance to hydrolysis and can withstand prolonged exposure to moisture without significant degradation.

Electrical Insulation: POM is an effective electrical insulator with good dielectric properties. It offers excellent resistance to electrical conductivity and is commonly used in electrical and electronic applications.

Machinability: POM is easily machined, allowing for precise and complex part manufacturing. It can be readily turned, milled, drilled, and tapped, making it a preferred choice for producing detailed components.

Stainless Steel 316

316 Stainless Steel is a highly corrosion-resistant austenitic stainless-steel alloy with excellent mechanical properties. It is widely used in various industries, including construction, automotive, aerospace, marine, and medical, due to its superior corrosion resistance, high strength, and versatility.

Characteristics of 316 Stainless Steely

Corrosion Resistance: 316 Stainless Steel exhibits excellent corrosion resistance, particularly in aggressive environments containing chlorides, acids, and marine atmospheres. It has superior resistance to pitting corrosion, crevice corrosion, and stress corrosion cracking.

High-Temperature Performance: 316 Stainless Steel retains its mechanical strength and corrosion resistance at elevated temperatures. It offers good resistance to oxidation and maintains its integrity in high-temperature applications.

Mechanical Properties: 316 Stainless Steel possesses excellent mechanical properties, including high tensile strength, good ductility, and toughness. It can withstand heavy loads and is resistant to deformation under stress.

Aesthetic Appeal: 316 Stainless Steel has an attractive appearance with a smooth, polished surface. It is commonly used in architectural applications and decorative elements due to its aesthetic appeal.

Hygiene and Cleanliness: 316 Stainless Steel is non-porous, easy to clean, and resistant to bacteria and germs. It is commonly used in food processing, pharmaceutical, and medical industries where hygiene and cleanliness are critical.

Compatibility with Cryogenic Temperatures: 316 Stainless Steel maintains its mechanical properties and corrosion resistance at cryogenic temperatures, making it suitable for applications in extremely low-temperature environments.

Titanium

Titanium is a chemical element with the symbol Ti and atomic number 22. It is a lustrous transition metal known for its exceptional strength-to-weight ratio, excellent corrosion resistance, and biocompatibility. Titanium is widely used in various industries due to its remarkable properties.

Characteristics of Titanium:

Strength and Lightweight: Titanium has a high strength-to-weight ratio, making it exceptionally strong while being lightweight. It is about 45% lighter than steel but has similar strength, allowing for the construction of strong and durable structures without adding excessive weight.

Corrosion Resistance: Titanium exhibits excellent corrosion resistance, even in harsh environments. It forms a protective oxide layer on its surface, providing resistance to corrosive substances such as seawater, chlorides, acids, and industrial chemicals. This property makes titanium suitable for applications where corrosion is a concern.

Biocompatibility: Titanium is biocompatible, meaning it is non-toxic and well-tolerated by the human body. It is extensively used in medical and dental implants, such as hip and knee replacements, dental implants, and surgical instruments, due to its compatibility with human tissues and low risk of allergic reactions.

Heat and Cold Resistance: Titanium has a high melting point and can withstand extreme temperatures, making it suitable for applications in both high-temperature and cryogenic environments.

Excellent Strength and Stiffness: Titanium exhibits excellent mechanical properties, including high tensile strength, stiffness, and toughness. It can withstand heavy loads and resist deformation under stress.

Non-magnetic: Titanium is non-magnetic, making it suitable for applications where magnetic interference needs to be minimized, such as in certain electronic devices and medical equipment.

Available Equipment

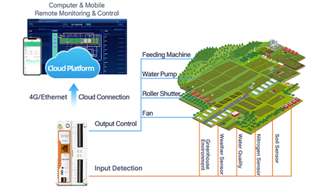

Basic Smart Farming IoT Systems

UO2-IOT Cloud Base Solution

Build your IoT system effortlessly – no coding required! Our comprehensive package comes complete with everything you need: Dashboard, Analytics, Storage, Notification, and Device and User Management. Manage devices seamlessly, collect and process data effortlessly, and visualize it all with ease. Enjoy low cost, high efficiency, scalability, safety, and reliability – all in one user-friendly platform.

Edge Computing-Edge acquisition, computing, control, Change reporting & Regular reporting

Linkage Control-Value trigger & IO trigger, Linkage DO output Transparent Transmission-TCP, UDP, HTTP, MQTT, Heartbeat pack, SSL

4G+Ethernet Port-CAT4 LTE Network, Wired & Wireless

MQTT-Custom topic, Custom Json

Modbus Gateway-Modbus RTU to TCP, Modbus RTU to Json

IO Controller-2DO, 2DI, 2AI, Extensible

IoT Platform– AWS, MQTT private server, PUSR Cloud, AliCloud

M100=G786+DI/DO/AI+MQTT/SSL

This solution comes with one UO2-M100 series controller and one EXTRA 8 CHANNEL UO2-IO0080 unit, software and 2hrs user support.

(System customizable. Site installation costs, RS485 cables, and owner installation support are provided according to site-specific conditions.) Data card and contract for client’s account.

UO2-Smart Farmer-IoTDB Box

Supply plug and play 686.210* IP56 380x300x120mm PVC Housing with duty cycle relay for 2 Directional – Ceramic Solenoid Ball Valve, 1x circuit breaker, and connections ready to receive UO2-IOT Cloud Base Solution hardware that can control max 10 x RS485 slave devices. (System customizable. Site installation costs, RS485 cables, and owner installation support are provided according to site-specific conditions.)

Multi and Single Parameter Controllers

UO2-MPWC1 Multi Parameters Water Quality Controller – OU2-WATER VIEW

Multi-parameters Analyzer and Display system includes: Multi-Parameters Transmitter Touch screen, RS485 Modbus, USB interface, with datalogger – Power:220VAC. The system includes programming, a High and Low relay for the DO sensor, and a Timer function. The system includes the following connections in the box and the programmer set up a system to be able to provide the following water quality parameters.

1. pH and Temp

2. Conductivity

3. DO

4. COD & BOD

5. Turbidity

6. Suspended Solid

7. Chlorophyll-a

8. Three in one out of water – CO2, Humidity, Ambient Temperature

9. Nitrate(NO3-) (System customizable. Site installation costs, RS485 cables, and owner installation support provided according to site-specific conditions.) Data card and contract for client’s account.

Industrial Single Parameter Online Controllers Screen: 0,8kg, 144*144*170mm unit with 192×64 LCD screen, IP65-best for outdoor use.

Calibration of sensors: Comes calibrated from the factory. When required again it is recommended that this is done by a specialist. Calibration software, training and step-by-step instructions will be provided.

Single-parameter: Customised controller – monitor COD, TOC, pH, temperature, dissolved oxygen, conductivity and other parameters.

Easy to integrate: Standard RS485 Modbus-RTU protocol and support for third-party device access in the field.

Power supply and usage: AC 220V – 3W Transmitting output: RS485

Installation method: Wall or panel mounting.

Alarm output: normally open contact relay (3A/250VAC) (System customizable. Site installation costs, RS485 cables, and owner installation support provided according to site-specific conditions.)

Industrial Online Controller Solutions

DOMC-02 Polarography DO Online Controller with sensor + spare sensor membrane cap.

Automatic temperature compensation function

Optional online data acquisition software

channel 4-20mA current output

4-20mA output can be reversely controlled

Support RS485 communication

groups of ON/OFF relay control

The memory storage function can store 50 records.

Support the loT system integration.

Watchdog function

Optional Automatic cleaning function

Screen: 0,7kg, 96*105*168mm unit with 192×64 LCD screen, IP65 – best for outdoor use.

Calibration of sensors: Comes calibrated from the factory. When required again it is recommended that this is done by a specialist. Calibration software, training and step-by-step instructions will be provided.

Single-parameter: Customised controller – monitor DO 0-20mg/L (15m cable on the sensor)

Easy to integrate: Standard RS485 Modbus-RTU protocol and support for third-party device access in the field.

Power supply and usage: AC 220V – 3W

Transmitting output: RS485 and 4-20mA Installation method: Wall or panel mounting.

Alarm output: normally open contact relay (3A/250VAC)

(System customizable. Site installation costs, RS485 cables, and owner installation support are provided according to site-specific conditions.) Data card and contract for client’s account.

DOMC-02 Polarography DO Online Controller with sensor + spare sensor membrane cap.

Automatic temperature compensation function

Optional online data acquisition software

channel 4-20mA current output

4-20mA output can be reversely controlled

Support RS485 communication

groups of ON/OFF relay control

Memory storage function can store 50 records.

Support the loT system integration.

Watchdog function

Optional Automatic cleaning function

Screen: 0,7kg, 96*105*168mm unit with 192×64 LCD screen, IP65 – best for outdoor use.

Calibration of sensors: Comes calibrated from the factory. When required again it is recommended that this is done by a specialist. Calibration software, training and step-by-step instructions will be provided.

Single-parameter: Customised controller – monitor DO 0-20mg/L (15m cable on the sensor)

Easy to integrate: Standard RS485 Modbus-RTU protocol and support for third-party device access in the field.

Power supply and usage: AC 220V – 3W

Transmitting output: RS485 and 4-20mA Installation method: Wall or panel mounting.

Alarm output: normally open contact relay (3A/250VAC)

(System customizable. Site installation costs, RS485 cables, and owner installation support are provided according to site-specific conditions.) Data card and contract for client’s account.

Portable and Pen-Type models

UO2-DO601-Pen type Dissolved Oxygen Tester

Features

- Measuring range: Dissolved Oxygen 0~20mg/L, Temperature 0~60℃

- LED segment code liquid crystal display (dissolved oxygen value and temperature value)²

- Numerical calibration and temperature calibration function

- Using a 32-bit high-performance processor, high stability, low power consumption

- Automatically identify the standard solution, if the wrong standard solution is used, the calibration cannot be completed.

- Automatic shutdown after five minutes without key operation

- Low battery reminder function

- Long standby technology, theoretical standby time is more than one year.

- Protection grade: IP65

- Dissolved oxygen pen meter for fishing water NPT-DO601 pocket Dissolved Oxygen tester

Technical Parameters

- Resolution: 0.01mg/L, 0.1℃

- Accuracy: ±2%FS,±0.3℃

- Automatic temperature compensation: 0~60℃ NTC 10K

- Working conditions: ambient temperature is 0~60℃, relative humidity ≤90%

- Working voltage: rechargeable lithium battery 3.7V

- Size: Overall: 204mm×46mm Screen: 25mm×32mm.

- Weight:128g

UO2-PH106 Pen type PH Tester

Features

- Measuring range:pH 0.00~14.00 ,ORP -999mV~999mV,temperature:0~60℃

- LED segment code LCD display (pH/ORP value and temperature value)

- Numerical calibration and temperature calibration function

- Using 32-bit high-performance processor, high stability and low power consumption.

- 2 sets of calibration fluids: ①6.86 and 4.00 ②6.86 and 9.18, can be switched at will.

- Automatically identify the standard solution, the standard solution does not match, and the calibration cannot be completed.

- The pH/ORP mode can be switched freely, and the pH/ORP electrode head is easy to replace.

- Automatic shutdown after five minutes without key operation

- Low battery reminder function

- Long standby technology, theoretical standby time is more than one year

- Protection level: IP65

Technical Parameters

- Resolution:0.01pH/1mV, 0.1℃

- Accuracy:±0.02pH, ±2mV, ±0.3℃

- Automatic temperature compensation:0~60℃ NTC 10K

- Working conditions: ambient temperature is 0~60℃, relative humidity ≤90%

- Working voltage: NPT-PH101 button batteries 4×1.5V;NPT-PH106 rechargeable lithium battery 3.7V

- Size: Overall: 204mm×46mm, large screen(NPT-PH106): 25mm×32mm, small screen(NPT-PH101) :20mm×28mm

- Weight: NPT-PH101:111g; NPT-PH106: 128g

Other available meters and sensors

| Portable Dissolved Oxygen Tester Sensor: Galvanic Cell Method Measuringrange:0~20mg/L Resolution:0.01mg/L Accuracy:±2%FS Work temperature:0~60℃ Power: AA batteries, 1.5V*5 TEMP compensation: Automatic Cable Length: 5M | Portable Optical DO Meter Range: 0~20mg/L Output: RS485/Modbus Power: 6~12 V DC Housing material: SS316 Cable: 5m+1m |

| Pen type Residual Chlorine /Dissolved Ozone Tester Measuringrange:0-20mg/L Resolution:0.01mg/L Accuracy:±2%FS Work temperature:0~60℃ Charging Port: Type-C Power: Built-in Lithium battery Temperature display | Fluorescence Dissolved Oxygen Sensor Measuring Range: 0~20mg/L Power Supply: DC 6~12V Output Signal: RS485/Modbus Housing Material: SS316 Cable:15m |

| Digital PH sensor Measuring Range: 0~14pH Power Supply: DC 6~12V Output Signal: RS485/Modbus Housing Material: POM Cable:15m | Digital ORP Sensor Measuring Range:-999~999mV Power Supply: DC 6~12V Output Signal: RS485/Modbus Housing Material: POM Cable:15m |

| Digital Conductivity Sensor Measuring Range:1uS/cm ~300 mS/cm Power Supply: DC 6~12V Output Signal: RS485/Modbus Housing Material: PEEK Cable:15m | Digital salinity sensor Measuring Range:1uS/cm-300 mS/cm Power Supply: DC 6~12V Output Signal: RS485/Modbus Housing Material: SS316 / POM Cable:15m |

| Digital TDS sensor Measuring Range:1uS/cm-300 mS/cm Power Supply: DC 6~12V Output Signal: RS485/Modbus Housing Material: SS316 / POM Cable:15m | Fibre Optic Chlorophyll-a Sensor Range: 0~400 ug/L or 0 ~100 RFU Output: RS485/Modbus Power: 6~12 V DC Housing material: SS316 With Self-cleaning brush Cable: 15m |

| NH4-N Ammonia Nitrogen Sensor Measuring Range: 0-1000mg/L Power Supply: DC 6~12V Output Signal: RS485/Modbus Housing Material: POM Cable: 15m | Nitrate Sensor Measuring Range:0~1000mg/l Power Supply: DC 6~24V Output Signal: RS485/Modbus Optional: Potassium/Sodium Housing Material: POM Cable: 15m |

| Fiber Optic Turbidity Sensor Measuring Range: 0 to 4000 NTU Power Supply: DC 6~12V Output Signal: RS485/Modbus Housing Material: POM/Titanium Self-cleaning System: NO Cable: 15m | Total Suspended Solids Sensor Measuring Range:0~1000mg/L Power Supply: DC 6~12V Output Signal: RS485/Modbus Housing Material: POM Self-cleaning System: Yes Cable: 15m |

| Blue-green Algae Sensor Measuring Range:0-270, 000 cells/mL Power Supply: DC 6~12V Output Signal: RS485/Modbus Housing Material: SS316 / Titanium Self-cleaning System: yes Cable: 15m | COD & BOD sensor Measuring Range: 0~ 6000 mg/Customizable) Power Supply: DC 6~12V Output Signal:RS485/Modbus Housing Material: SS316 Cable: 15m |

| Dissolved Ozone Sensors | UO2-Online Residual Chlorine Sensor Measuring Range:0~40.00mg/L (HClO) Power Supply: DC12~24V Principle: Constant voltage method Output Signal: RS485/Modbus Cable: 15m |

Smart Farmer Weather Station Solution

| 3-in-1 CO2 Temperature and Humidity Transmitter CO2:0~5000ppm Humidity:0~100% Temperature:0~50C Power:10~30V COMM: standard RS485 Modbus | Complete Smart Farmer Weather station solution 1 x Basic Weather Station, 1 x Fish House Industrial Temp/Hum, 1 x wind direction and speed, water temp probes. COMM: standard RS485 Modbus |

| UO2-BWHT-1 Basic Weather Humidity and Temperature Industrial sensor RS485 Modbus Humidity:0~100% RH Temperature:-40~+80℃ Power:10~30V Resolution: 0.1℃,0.1%RH Accuracy::±0.5℃(25℃),±3%RH (60%RH,25℃) Temp range: -40~+85℃ Accuracy:±0.5℃ Stainless steel temp probe | Basic Weather Wind Speed and Direction transmitter – Aluminium coated with plastic. RS485 output Range:0-70m/s – 0-360°or 16 directions Resolution:0.1m/s and 1° BWST-01-Basic Weather Station Range: temp:-40~+120℃ Humidity:0~99%RH Air pressure: 0~120Kpa Lighting:0~20 Wlux |

IMPORTANT TO REMEMBER

IF YOU CAN’T MEASURE IT, YOU CAN’T MANAGE IT

Embarking on a journey without the proper tools and guidance can transform what should be an exciting adventure into a nerve-wracking and uncertain endeavour. Just like driving a vehicle without reliable speed and fuel gauges, the path ahead can become stressful and laden with risks.

But fear not, our mission is to empower water treatment customers, especially visionary farmers who have invested millions in their infrastructure, with the remarkable gift of informed choice. Together, we illuminate the way towards optimal instrumentation and ingenious Smart Farmer solutions.

We embraced these available cutting-edge solutions and can transcend the boundaries of uncertainty and step into a realm of enhanced productivity and flourishing returns on investments. Your journey into the new world of IoT and environmental monitoring and management is our shared commitment, and together, we shall find the appropriate long-term cost-effective site-specific solution for you.

Warranty & Maintenance

The importance of preventative maintenance is etched into the very fabric of advancement. It is the guardian of reliability, the gatekeeper of precision, and the sentinel of success. All sensors or parts of sensors need to be replaced at some point. We understand that no sensor lasts forever and therefore focus on sensors that are reliable, affordable and make practical sense.

We take pride in helping clients to minimise lifecycle costs on instrumentation and sensors. Furthermore, the value of foresight cannot be overstated when it comes to choosing the appropriate instrumentation and sensors.