Waste Water

Revolutionising wastewater treatment

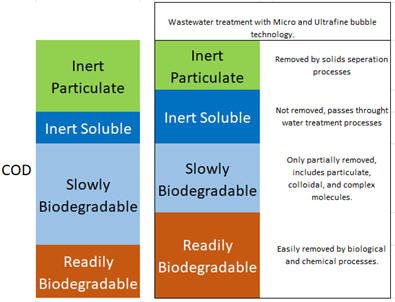

Welcome to our wastewater solution! In the world of water and wastewater treatment, aeration is a crucial process. It involves delivering oxygen to microorganisms responsible for the biological oxidation of carbonaceous material and ammonia. These aerobic processes are the backbone of degrading pollutants like biological oxygen demand (BOD), chemical oxygen demand (COD), total Kjeldahl nitrogen (TKN), and ammonia in water. Dissolved oxygen (DO) levels are pivotal in controlling these aerobic processes effectively.

However, many treatment facilities face challenges with insufficient dissolved oxygen. This can be due to factors such as excessive loading, underperforming aeration systems, or outdated designs. Low dissolved oxygen levels create an environment conducive to the growth of filamentous bacteria, leading to issues like sludge bulking and foaming, disrupting the treatment process. Moreover, it can result in poor treatment efficiency and potential violations of discharge regulations.

Expanding aeration capacity to address these issues can be both complex and expensive. That’s where our Ultra-OXYGEN Micro and Ultrafine Bubble generators come in. Our innovative technology offers a solution that can replace and supplement underperforming aeration systems, delivering biologically available dissolved oxygen precisely where it’s needed. This approach is not only rapid but also cost-effective and modular, ensuring efficient support for the biological processes vital for effective wastewater treatment.

With our cutting-edge solution, you can optimize your wastewater treatment, reduce operational challenges, and enhance overall treatment efficiency. Join us on the journey to cleaner water and a more sustainable future.

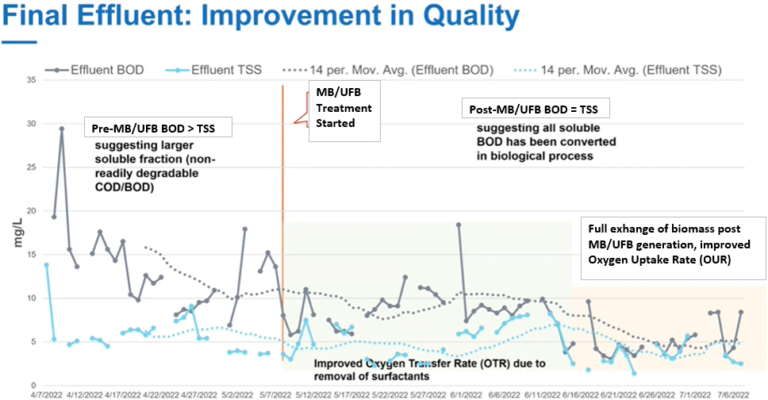

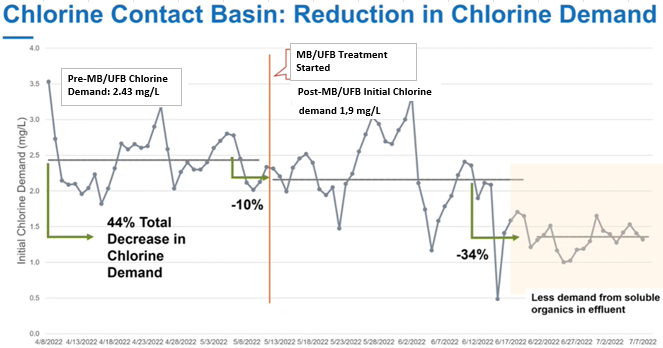

Below expected results that can be achieved

Business Case

Introducing a Compelling Business Case for Ultra-Oxygen Micro and Ultrafine Bubble Technology

In the realm of wastewater and water treatment, innovation is key to achieving superior results. Enter Ultra-Oxygen’s groundbreaking Micro and Ultrafine bubble technology, featuring an award-winning patented nozzle type that is revolutionizing the industry.

What sets our technology apart is its remarkable ability to generate substantially larger quantities of Micro and Ultra-Fine bubbles in water with higher viscosity. This unique character translates into a higher capacity for dissolving gas in water, making it a game-changer for efficient gas dissolution processes. Specifically, our state-of-the-art units, the 1N-VIPER, 1N-PvC, and VIPER-30, excel at dissolving gases like oxygen in water with up to 90% more efficiency than traditional aeration equipment.

But that’s not all. Our technology offers precise control over bubble size and airflow, enabling us to boost dissolved oxygen (DO) levels up to 30 times faster than outdated aerators. This remarkable capability significantly accelerates the biological oxidation of contaminants, such as organic compounds and ammonia, in water and wastewater treatment processes.

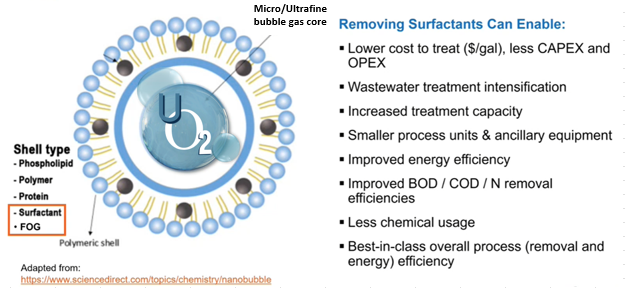

One of the key advantages of our technology is its ability to remove surfactants effectively. Surfactants are compounds often found in wastewater that can be challenging to treat. Our Micro and Ultrafine bubble technology excels at surfactant removal, which not only improves overall treatment efficiency but also results in numerous benefits:

- Unparalleled Efficiency: Our technology’s ability to dissolve gases more efficiently means faster and more effective water treatment, reducing treatment time and operational costs.

- Environmental Impact: By promoting the rapid degradation of pollutants, we contribute to a cleaner environment and help organizations meet stringent regulatory standards.

- Versatility: Our modular and adaptable approach suits a wide range of industries, including agriculture, aquaculture, and wastewater treatment, offering a versatile solution for diverse water treatment challenges.

- Cost Savings: Faster treatment processes and reduced chemical usage translate into substantial cost savings for businesses and municipalities.

- Sustainability: We align with sustainability goals by enhancing the effectiveness of bioremediation processes and promoting eco-friendly treatment methods.

In summary, Ultra-Oxygen’s Micro and Ultrafine bubble technology not only represents a breakthrough in water treatment but also an opportunity for businesses and organizations to optimize their processes, reduce operational complexities, and contribute to a more sustainable future. Join us in revolutionizing the way we treat water and wastewater—efficiency, sustainability, and effectiveness, all in one innovative solution.

Problems or issues shared with us by engineers and farmers are solved

As a key component in water treatment solutions, dissolved oxygen (DO) holds a central role, often referred to as the “Queen Bee”. It is critical for engineers to possess a thorough understanding of the required oxygen levels and the methods for supplying them efficiently.

It is of utmost importance for engineers to comprehend the recent advancements in utilizing pure oxygen (PO) and ozone effectively in combination with micro and ultrafine bubble generators. Implementing these technologies into designs can greatly enhance their performance.

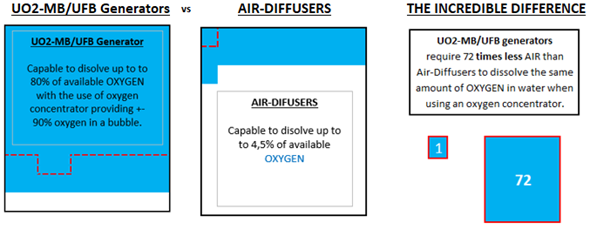

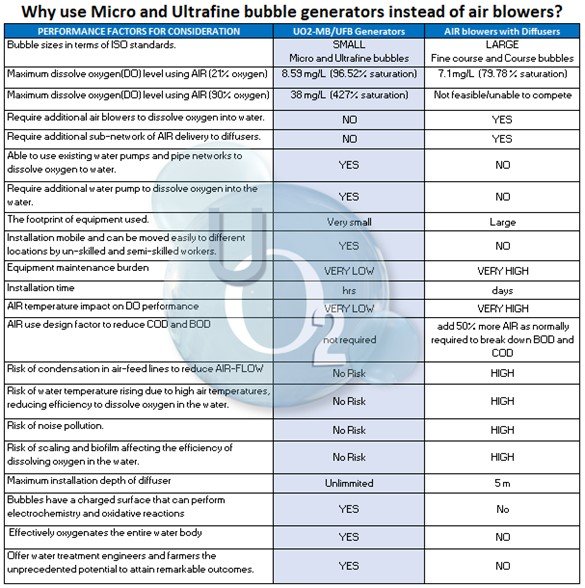

Our tests have demonstrated that PO can be utilized with remarkable efficiency, as compared to traditional air blowers widely used in wastewater treatment plants. In fact, our results have shown that using PO with UO2-MB/UFB generators can achieve the same results while consuming 72 times less air.

Our technology used demonstrated that it improves the treatability and efficiency of wastewater treatment, mainly due to the ability to remove surfactants, enabling Lower cost to treat (less CAPEX and OPEX), Wastewater treatment intensification, Increased treatment capacity, Smaller process units & ancillary equipment, Improved energy efficiency, Improved BOD / COD / N removal efficiencies, Less chemical usage, Best-in-class overall process (removal and energy) efficiency.

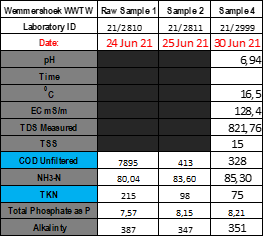

An engineer at the local municipality requested a trial to test the time it will take to raise the dissolved oxygen levels in raw sewer water and to see what will happen with the water quality BEFORE it is treated.

We observed that we could again increase the DO very effectively from 0.52mg/L up to 26mg/L within 4 hours with only one 1N-PvC using 2.5 L/min pure oxygen (PO) in a 10 000L tank, after stabilising the load within 12 hours, despite the high COD load of 7 895 mg/L received. The aeration time needed after 1 day was 30 min every +- 15 hrs to keep the DO levels between 18 and 37.5 mg/L. Below some of the key results recorded.

So what does this all mean? Taking into consideration that aeration accounts for 25-60% of the total energy consumption of a wastewater treatment plant, it is a no-brainer that this is where you need to focus if you want to save money. Ultra-Oxygen does way more than that.

We can cut old aeration equipment’s electricity bills up to 90%, recover lost DO levels within hrs, reduce the use of chemicals drastically, drastically reduce the cost of sludge management, and produce discharge water at healthy levels suitable for re-use.

- Over 100,000,000 old-type “fine” bubble diffuser units are installed in thousands of treatment plants worldwide. ISO now classified these units as producing SMALL COURSE BUBBLES, not fine bubbles.

- Over 10,000,000 coarse bubble diffuser units are installed in thousands of treatment plants worldwide. They can now all be replaced by Micro/Ultrafine bubble generators outperforming these old dinosaurs on every level thinkable level.

- Bottom-up aeration is now possible with Top-Down maintenance capabilities.

- MB/UFB equipment is easy to install and has a turnaround time of seeing results within 2-14 days.

- Over 900 Billion litres of Wastewater are Treated per Day with outdated aeration equipment piling up energy consumption costs.

Oxygen Transfer Efficiency & Transfer Rates Compared

| System | Oxygen Transfer Efficiency % ( @ 4.572 m depth ) | Oxygen Transfer Rate ( kg/kW-hr ) |

|---|---|---|

| Ultra-Oxygen MB/UFB Generators | 40-65 | 25 – 45 |

| Fine-Micro Bubble Generators [old incorrect terminology – Micro Bubble Generators] | – | 6.1 – 16.47 |

| Fine Course Bubble Diffuser [(old incorrect terminology – Fine Bubble Diffusers] (total floor coverage) | 22-32 | 3.66 – 3.965 |

| Fine Course Bubble Diffuser [(old incorrect terminology – Fine Bubble Diffusers] (side wall installation) | 18-20 | 2.135 – 2.745 |

| Jet Aerators [Medium Course Bubble – old incorrect terminology – fine bubble] | 18-25 | 1.83 – 2.135 |

| Static Aerators [Medium Course Bubble – old incorrect terminology – medium bubble] | 10-12 | 1.403 – 1.708 |

| Mechanical Surface Aerators [Large Course Bubble] | – | 1.525 – 2.135 |

| Large Coarse Bubble Diffusers (wide band pattern) [old incorrect terminology – Course Bubble Diffusers] | 8-12 | 1.22 – 1.83 |

| Large Coarse Bubble Diffusers (wide band pattern) [old incorrect terminology – Course Bubble Diffusers] | 6-8 | 0.915 – 1.22 |

Where is aeration implemented to treat wastewater?

What are the expected benefits?

- Production of a large amount of Micro and Ultrafine bubbles with extremely high oxygen dissolubility.

- Increased saturation of dissolved oxygen in the water.

- Compact, portable, and easy installation.

- Low energy consumption (only 250W, 400W, 1.5kW).

- Low and easy maintenance.

- Mixing and reducing the biofilm media.

- To maintain the DO level for the survival of aerobic bacteria.

- For BOD removal at a fast rate and for the Nitrification process.

- Maintain the aesthetic condition of the water.

- To avoid foul smell.

WWTP’S MAIN COSTS FACTORS

The aeration system consumes approximately 50 to 70% of the net power demand for a typical activated sludge wastewater treatment plant. Therefore, the designer is responsible for selecting a system that will meet the mixing and oxygen requirements for the process at the lowest cost possible. Once the criteria for aeration are determined, comparative costs for different types of aeration systems can be estimated, and the final equipment configuration can be selected to best match the job’s requirements.

Construction cost items mainly consist of aeration basins, air piping and headers as appropriate, aeration devices and their supports, air cleaning equipment, blowers, and buildings to house these items.

New vs. Old Aeration Calculations

Assumed:

Oxygen required per aerator = 77.9 kg/h

Correction factor for site solubility = 1.071 Correction factor for minimum DO in aeration tank = 1.217

The old way of calculating:

Assume transfer efficiency of 2.0 kg oxygen/kWh for slow-speed aerators into clean water under standard conditions and an alpha factor of 0.85 for transfer into mixed liquor Aerator power required = 77.9/(2.0 x 0.85) x 1.071 x 1.217 = 59.7 (say) 60 kW per aerator and 60 x 6 = 360 kW for say six aerators. (402kW).

In specifying aerators, it should be borne in mind that allowance should be made for motor and gearbox efficiency. It is common practice to select a service factor of 2.0 for the gearboxes and to allow 10 to 15% additional motor capacity (say 67 kW motors in the present case).

“When using the Ultra-Oxygen MB/UFB technology, the calculations look different.”

The new way of calculating:

Assume transfer efficiency of 65.88 kg oxygen/kWh for slow-speed aerators into clean water under standard conditions and an alpha factor of 0.85 for transfer into mixed liquor Aerator power required = 77.9/(65.88 x 0.85) x 1.071 x 1.217 = 1.813 (say) 2 kW per aerator and 2 x 6 = 12 kW for all six aerators.

No allowance is necessary for motor and gearbox efficiency because the unit is driven by a pump.

- Massive saving OF 3 350 % on electricity alone.

OTHER SAVINGS:

- The Ultra-Oxygen can eliminate the construction costs related to blower rooms and associated equipment.

- 430 % more efficient than disc diffusers in dissolving oxygen in the water.